Description

A new glass substrate that meets the needs of the semiconductor and MEMS packaging (mounting) markets through featuring a wide coefficient of thermal expansion (CTE) range.It has features such as cover glass, various optimal CTEs as a supporting substrate, and flatness/smoothness.It supports wafers approximately φ300mm in size to panels approximately 500mm2 in size.

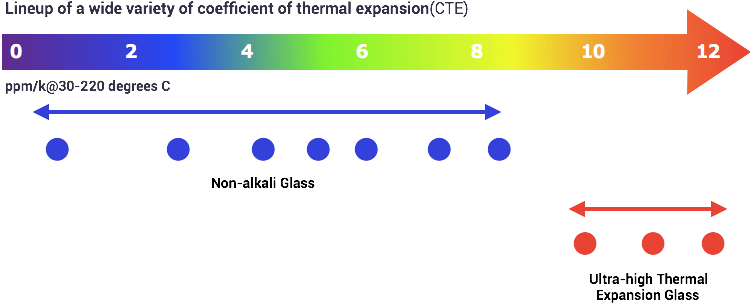

Lineup of unconventional coefficient of thermal expansion (CTE)

In recent years, the technology of packaging in a state of wafer (wafer level packaging) has become widespread, replacing the conventional packaging by individual piece. As a result, the needs are growing for glass as a cover for optical devices like an image sensor, as well as a support substrate in the packaging process of semiconductor and MEMS. Especially in the case of large diameter like φ300mm, reduction in both productivity and reliability is derived from the causes such as wafer warpage at a customer’s process due to the mismatching of coefficient of thermal expansion (CTE) between glass and silicon or material for semiconductor packaging, as well as the finished device warpage in an actual use environment.

AGC offers a glass wafer and a glass panel which contributes to resolving these issues, and are high quality and easy to use, through a lineup of the glass with unconventional and wide coefficient of thermal expansion (CTE) by making use of design capability of glass composition and production technology. We have a product lineup including non-alkali glass which perfectly matches with the CTE of Si, high expansion non-alkali glass, and ultra-high expansion glass.

Various sizes, support of plate thickness, high flatness/smoothness

It can support a panel size equivalent to φ300mm or □500mm, a thin sheet of 0.4mmt and others, and a plate thickness of 1.5mmt and others.

Additionally, it also supports the requirements of high flatness and high smoothness such as total thickness variation (from 1um), surface roughness (from 0.5nm), etc.

Features

- Lineup of coefficient of thermal expansion with wide variety from a perfect match with silicon to ultra-high expansion

- Abundant lineup of non-alkali glass

- Support a wafer size with φ300mm and others, and a panel size equivalent to □500mm and others

- Support a thin sheet with 0.4mm and others, and a plate thickness of 1.5mmt and others

- Support high flat (total thickness variation) and high smooth (surface roughness)

- Support notch, serially numbering, and noncontact/contact packaging

Product Applications

- Cover glass substrate for wafer level packaging

- Back-grinding glass and support glass substrate for wafer level packaging

- Support glass substrate for panel level packaging